The world of manufacturing and prototyping has been revolutionized by 3D printing technology, including in Malaysia. It has not only transformed the way we create objects but has also made the production of complex designs more accessible than ever before.

Among the various 3D printing technologies available today, Stereolithography (SLA) and Digital Light Processing (DLP) stand out as two prominent contenders. In this article, we will look into these technologies, their key components, benefits and applications. Choosing the right 3D printing technology can be a crucial decision, and we aim to provide the information you need to make an informed choice.

SLA 3D Printing

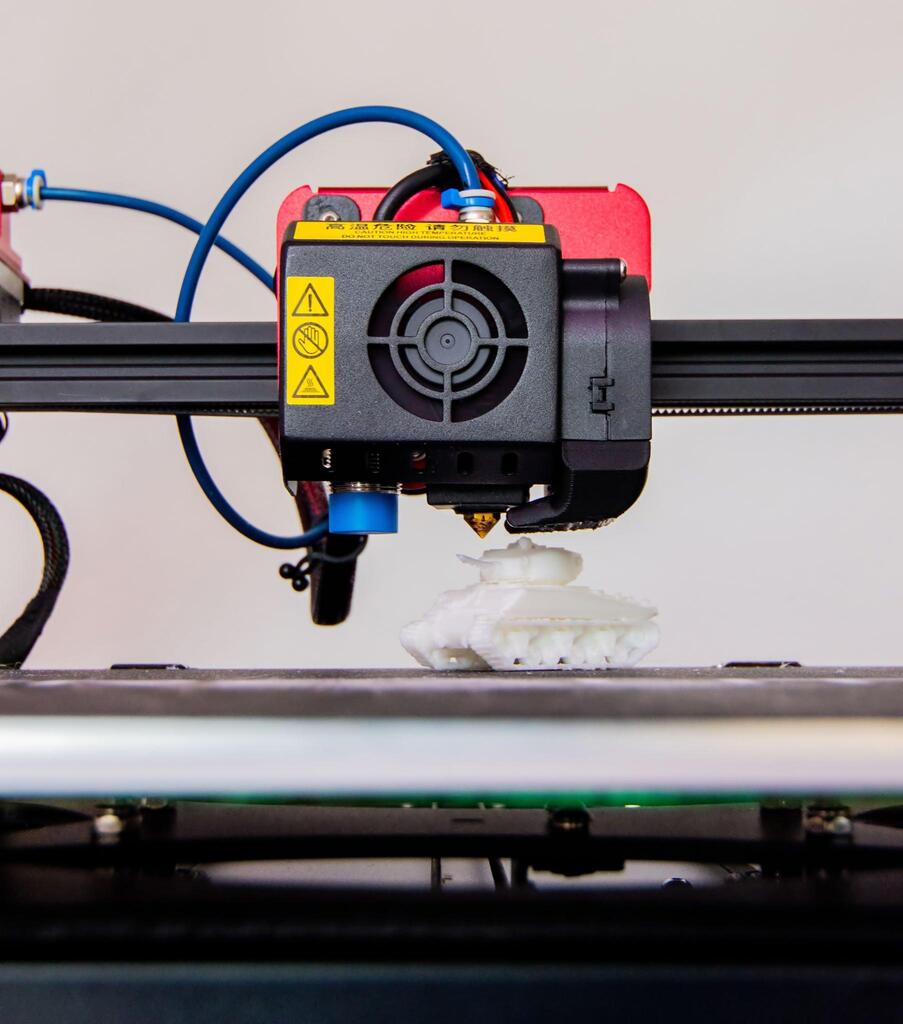

Stereolithography (SLA) is the most widely used 3D printing technology, commonly found in 3D printing shops in Malaysia. It operates on the principle of photopolymerization, where a liquid resin is selectively cured layer by layer using a UV laser or light source. This process results in the solidification of the resin into the desired 3D shape.

Advantages of SLA Technology

SLA technology offers several advantages:

High Precision: SLA printing produces objects with exceptional detail and accuracy, making it suitable for intricate designs and models.

Smooth Surface Finish: SLA prints have a smooth surface finish with minimal visible layer lines, reducing the need for post-processing.

Wide Material Compatibility: SLA can work with a variety of resin materials, including those with specific properties such as flexibility or transparency.

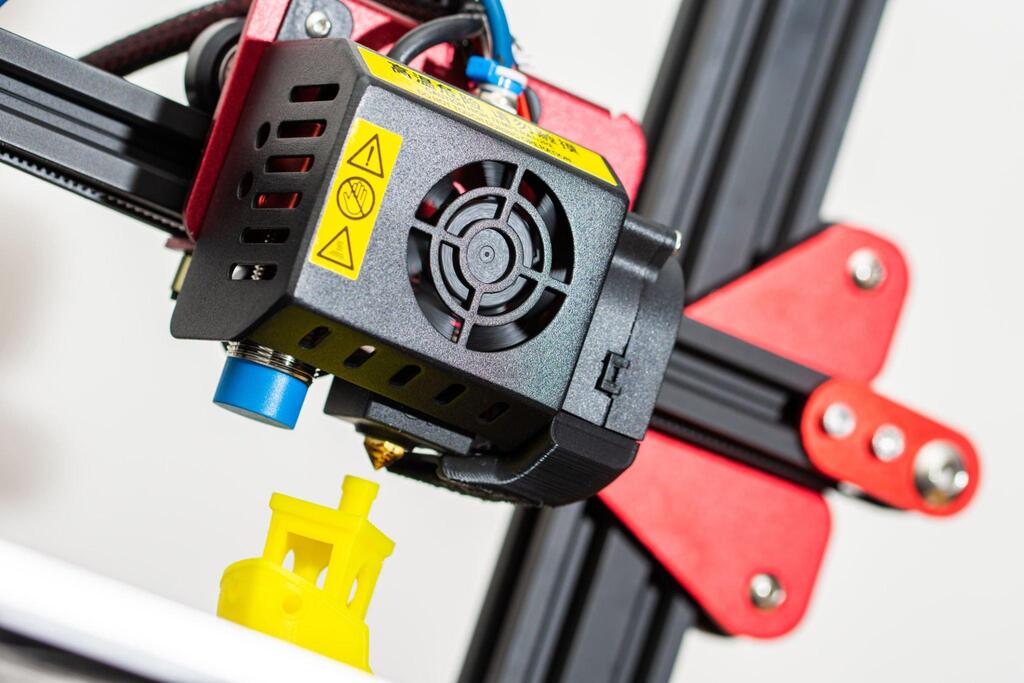

DLP 3D Printing

Digital Light Processing (DLP) is another 3D printing technology that relies on photopolymerization. However, unlike SLA, DLP uses a digital light projector to cure entire layers of resin simultaneously. This projector exposes an entire layer of the object to light, solidifying it all at once.

Benefits of DLP Technology

DLP technology offers its own set of advantages:

Speed and Throughput: DLP is known for its rapid printing speed, making it suitable for projects that require quick turnaround times.

High Resolution: DLP technology can achieve high resolution prints with intricate details, rivaling SLA in terms of precision.

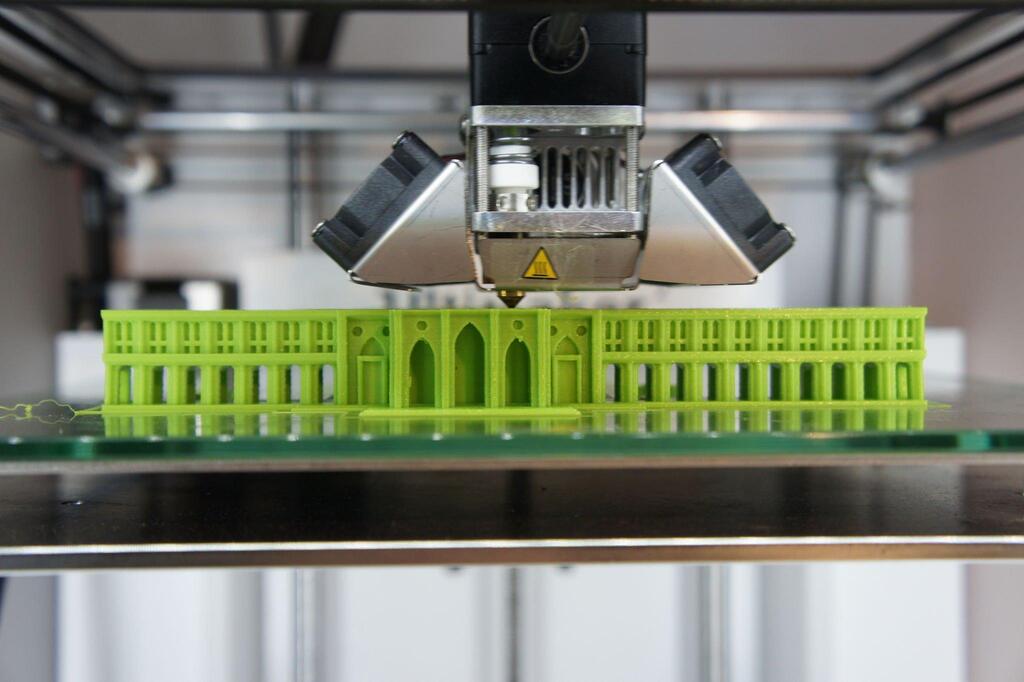

Large Build Volumes: DLP printers often have larger build volumes, allowing for the creation of larger objects or multiple smaller objects in a single print.

Side-by-Side Comparison: SLA vs. DLP

Printing Mechanism

Light Source: SLA uses a UV laser for precise point-by-point curing, while DLP employs a digital light projector for layer-wise curing.

Resin Container: Both technologies use a vat of liquid resin for building objects.

Resolution and Accuracy

SLA and DLP are neck and neck in terms of resolution and accuracy, with both capable of producing highly detailed and precise prints.

Print Speed and Throughput

DLP is generally faster than SLA due to its simultaneous layer wise curing, making it a better choice for projects with tight deadlines.

Pros and Cons of SLA 3D Printing

Advantages

High Precision: SLA 3D print is renowned for its exceptional precision and detail. It’s capable of producing intricate designs and complex geometries with utmost accuracy.

Wide Material Compatibility: SLA technology offers versatility in material selection. Whether you require standard resins, flexible materials or transparent options, SLA can accommodate a broad range of materials to meet your specific project needs.

Limitations

Slower Printing Speed: It is relatively slower printing speed compared to some other 3D printing technologies. The point-by-point curing process can lead to longer production times.

Post-Processing Challenges: SLA post-processing can be more complex. The need for support structures and the possibility of resin residues may require additional effort to achieve a smooth finish.

Pros and Cons of DLP 3D Printing

Advantages

Faster Printing Speed: DLP 3D printing stands out for its rapid production capabilities. It can create objects at a significantly faster pace compared to SLA technology.

Consistent Print Quality: DLP technology offers consistent and uniform print quality throughout the entire build platform. This ensures that every part of your project maintains the same level of accuracy and detail.

Limitations

Limited Material Compatibility: While DLP technology is efficient and precise, it has a more limited range of compatible materials compared to SLA.

Resolution Trade-offs: Achieving the same level of detail and precision as SLA can sometimes come at a cost. DLP technology may require trade-offs in resolution when printing objects with intricate features.

Choosing the Right Technology for Your Project

When deciding between SLA and DLP 3D printing technologies, several crucial factors should guide your choice:

Project Requirements:

Assess the specific requirements of your project. Consider the complexity of your designs and the desired finish.

Budget Constraints:

Evaluate your budget. SLA printers tend to be more expensive. DLP may offer a more cost-effective solution for projects with budget constraints.

Materials Needed:

Determine the type of materials required for your project. If you need a material that SLA supports but DLP doesn’t, your decision may become more straightforward.

Conclusion

In the exciting world of 3D printing technologies, SLA and DLP offer distinct advantages and limitations. SLA stands out for its precision and material versatility, while DLP excels in speed and consistent print quality. By carefully considering your project requirements, budget constraints, and material needs, you can select the technology that aligns best with your goals. Embrace the possibilities these technologies offer, and venture into the world of 3D printing with confidence, knowing that you’ve chosen the right tool for your creative endeavors.