Miniature 3D print is an exciting endeavor that marries the worlds of art and technology. Whether you are crafting intricate models for a tabletop game, designing detailed architectural structures or simply indulging in the hobby of miniatures, achieving a perfect print is both a science and an art.

Here are some indispensable tips to ensure that your miniature 3D prints come out looking their best.

1. Choose the Right Material

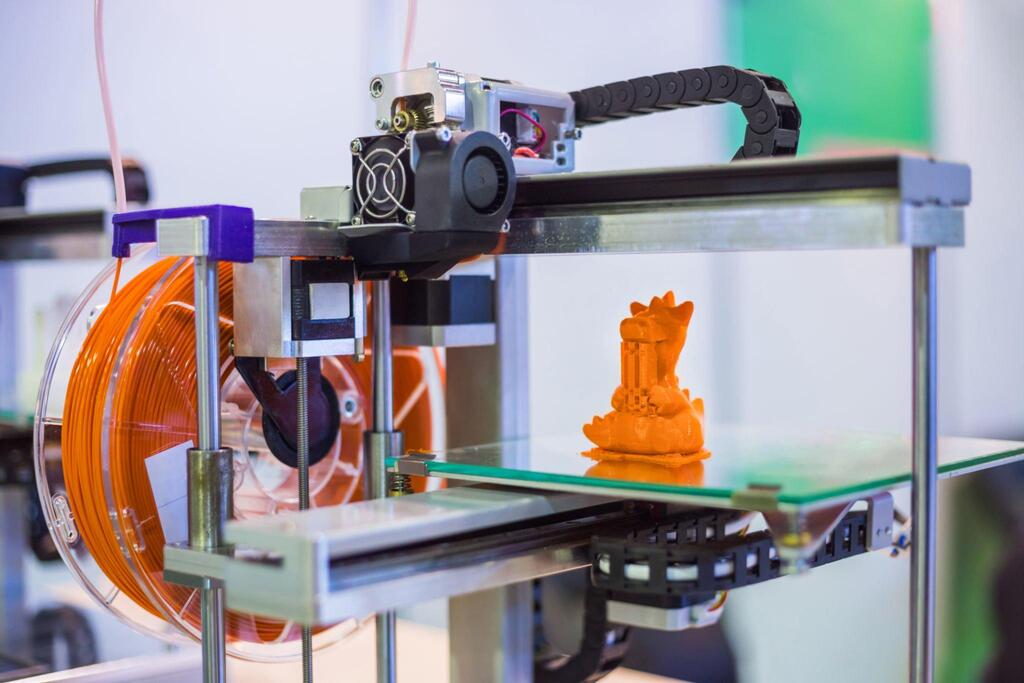

Material selection is paramount when aiming for detailed and high quality miniature prints. While PLA is the most common filament used due to its ease of printing, ABS and PETG are also popular choices for their durability. For super fine detail, consider using resin printers which allow for extremely high resolution prints.

2. Optimize Resolution Settings

The layer height is crucial when it comes to miniatures. A smaller layer height, such as 0.1mm or even 0.05mm, will provide a smoother finish and more detail. Keep in mind, though, that decreasing layer height will increase print times.

3. Use Slow Print Speeds

When aiming for precision over speed, slow down your print. A slower print speed (around 20-40mm/s) can drastically reduce errors and improve the overall quality of your miniature.

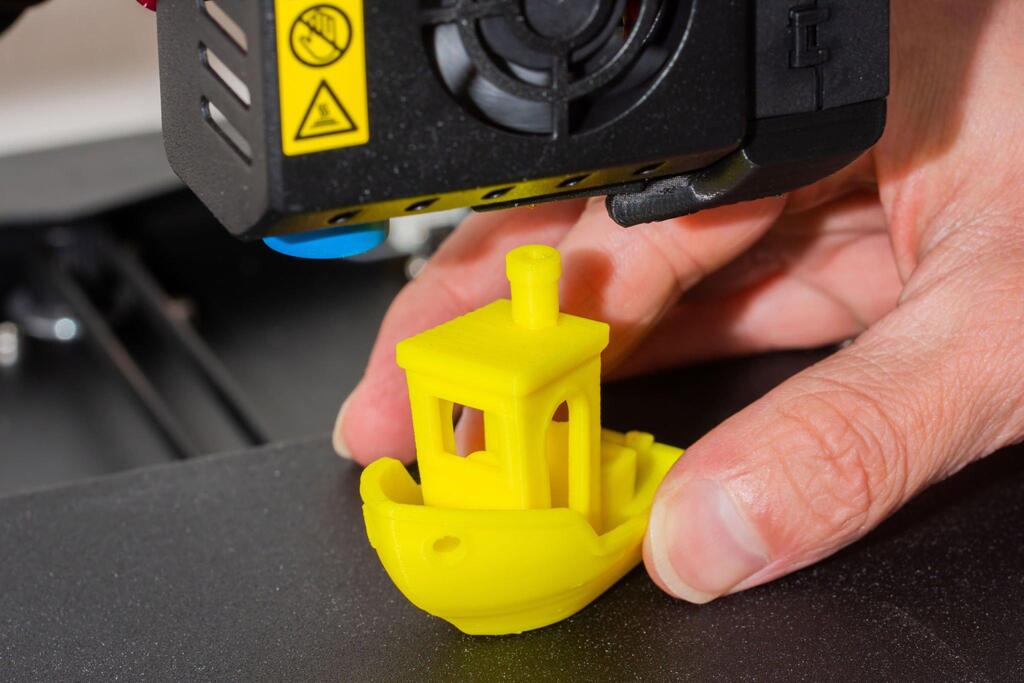

4. Improve Bed Adhesion

There is nothing more frustrating than a print that warps or detaches from the print bed. Use a heated bed, apply a layer of bed adhesion spray, or consider using painter’s tape or a glue stick to help your print stick better. For resin printers, ensure that the build plate is properly leveled and cleaned.

5. Invest in Post Processing Tools

The work does not end once your miniature is printed. Tools like needle files, fine grit sandpaper and craft knives can be used to clean up and refine your model. Smooth out layer lines, remove support marks, and bring out those delicate features.

6. Incorporate Supports Strategically

Supports are necessary to prevent overhangs from drooping. However, they can leave unsightly marks on your miniature. Use slicer software to add custom supports only where needed and try using tree-like supports which can be easier to remove.

7. Mind the Temperature

Maintaining a stable temperature is essential. Enclosing your printer can help in maintaining a consistent temperature environment, reducing warping and other temperature related issues. For resin printing, ensure the resin is at the recommended temperature, as it can influence the curing process.

8. Calibration is Key

Ensure that your 3D printer is well-calibrated. Regularly check the bed leveling, belt tension and ensure the extruder is clean and not clogged. A well maintained machine is more likely to produce flawless miniatures.

9. Experiment with Infill Patterns

While you might be tempted to save on material with a low infill percentage, sometimes a denser infill can add strength and weight, making the miniature feel more solid. Experiment with various infill patterns to see what works best for your model.

10. Stay Updated on Software

3D printing software and slicers are continually evolving. Staying updated ensures you’re utilizing the latest algorithms and settings optimized for print quality. It’s also worth experimenting with different slicers as some may handle miniatures better than others.

11. Test and Iterate

Every 3D printer has its quirks. Before printing a full, detailed miniature, consider doing some test prints to determine the best settings for your machine. Simple calibration models can help you pinpoint areas of concern and adjust your settings accordingly.

12. Seek Community Input

The 3D printing community is vast and always willing to share insights. Join forums, watch tutorials, and don’t be afraid to ask questions. Gleaning knowledge from others’ experiences can save you time and potential frustrations.

Applications of Miniature 3d Print

Miniature 3D printing has a wide array of applications across various industries and hobbies. The ability to produce detailed, small scale models has unlocked numerous opportunities and solutions. Here are some of the primary applications of miniature 3D printing:

Jewelry Design: Jewelers utilize miniature 3D printing to create intricate patterns and prototypes for rings, necklaces, earrings and other ornamental pieces.

Film and Animation: Miniature sets, props, and characters can be 3D printed for stop-motion animation, special effects or as visual aids in the filmmaking process.

Architectural Models: Architects and urban planners use miniature 3D printing to create scale models of buildings, landscapes and entire city blocks to visualize and present their designs.

Medical Models: In healthcare, miniature 3D printing helps in creating detailed replicas of human organs, tissues and skeletal structures for educational purposes or to assist in surgical planning.

Conclusion

Miniature 3D print is a rewarding journey that combines patience, technical know how and an eye for detail. As technology continues to advance, we can only anticipate even better, more detailed results in the world of miniatures. By adopting these tips and continually refining your process, you’ll be on your way to producing miniatures that are not only structurally sound but also breathtakingly detailed.