The world of manufacturing has undergone a revolutionary transformation in the last decade, with the advent of 3D printing. One of the most commonly used 3D printing technologies today is Fused Deposition Modeling (FDM). Malaysia, as an emerging economy in Southeast Asia, has recognized the potential of this technology and has been at the forefront in harnessing its capabilities. This article provides an overview of FDM 3D printing in Malaysia, including its growth, applications, challenges and the future prospects.

A Brief Overview of FDM 3D Printing

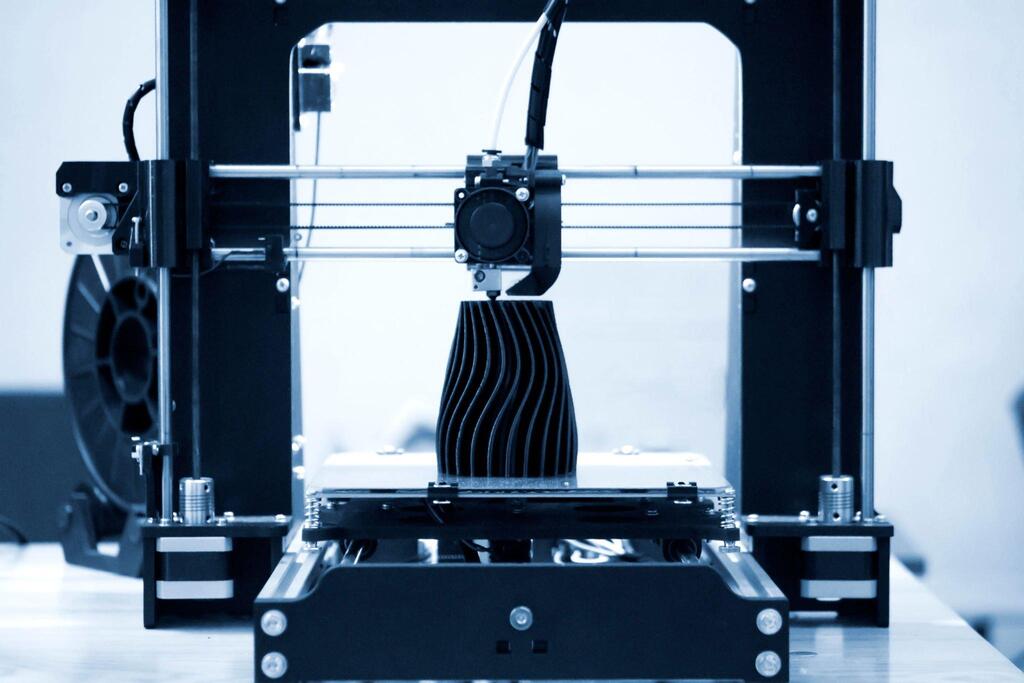

FDM is a 3D printing process that builds objects layer by layer by melting and extruding thermoplastic filament material. This material is then deposited onto a build platform in a pre-defined pattern. As each layer solidifies, the next layer is deposited on top, eventually creating a three-dimensional object. Due to its affordability, ease of use, and versatility, FDM has gained immense popularity both in industrial and domestic settings.

FDM, a technology originally developed in the late 1980s, gained prominence in Malaysia towards the late 2000s and early 2010s. Recognizing its transformative potential, Malaysian businesses, academic institutions, and even hobbyists started to explore this technology.

Growth of FDM 3D Printing Malaysia

Malaysia’s push towards becoming an advanced economy has been instrumental in the adoption of technologies like FDM 3D printing. The Malaysian government, through agencies such as the Malaysian Investment Development Authority (MIDA) and the Ministry of Science, Technology, and Innovation (MOSTI), has provided incentives for businesses to adopt 3D printing. The nation’s education sector has also played a role by integrating 3D printing into curriculums, thereby preparing future generations for an industry that values innovation.

Several startups and established companies in Malaysia have adopted FDM 3D printing as a primary or supplementary production method. These companies span multiple sectors, from automotive and aerospace to fashion and healthcare.

One of the primary reasons for the rapid uptake of FDM technology in Malaysia is its cost effectiveness. The printers, when compared to other 3D printing techniques like SLA or SLS, are more affordable, making them accessible to SMEs and educational institutions.

FDM 3D printers can use a plethora of materials, ranging from common plastics like PLA and ABS to more advanced composites. Malaysia’s thriving electronics and automotive industries found value in the versatility of materials used in FDM.

Applications of FDM 3D Printing in Malaysia

Medical & Dental

Customized implants, orthotics and prosthetics are being developed with the aid of FDM technology. This personalized approach enhances patient comfort and treatment outcomes.

Aerospace & Automotive

FDM 3D printing in Malaysia is contributing to the production of lighter and more fuel efficient parts, thus propelling the nation’s capability in these sectors.

Education

Many educational institutions have equipped their labs with FDM 3D printers, allowing students to transform their digital designs into tangible objects. This hands-on experience prepares them for careers in design, engineering and manufacturing.

Fashion & Art

FDM 3D printing is making waves in the fashion and art scenes in Malaysia. From intricate jewelry designs to avant-garde fashion pieces, the technology allows for immense creativity.

Construction

A few experimental projects in Malaysia have explored the possibility of using FDM 3D printing for constructing houses and buildings. While still in the early stages, this shows promise for addressing housing concerns in the future.

Challenges Faced by the FDM 3D Printing Industry in Malaysia

Despite its growth and potential, the FDM 3D printing industry in Malaysia faces certain challenges.

Skill Gap

Although the Malaysian education system has incorporated 3D printing into its curriculum, there remains a shortage of skilled professionals who can efficiently operate, maintain and innovate using FDM 3D printing. Training programs, while present, are still insufficient to cater to the industry’s growing demand. The country still lags behind global leaders in terms of technology adoption and expertise.

Material Dependency

Quality filament material is crucial for high-grade 3D printing. Much of these materials, especially specialized filaments, are imported, leading to dependency on foreign suppliers. This reliance can sometimes lead to increased costs and supply chain disruptions.

Initial Investment Concerns

While FDM printers are comparatively more affordable than other 3D printing technologies, for small businesses and startups, the initial investment can still be a barrier. This is coupled with the cost of continuous maintenance and material acquisition.

Competition from Neighboring Countries

Countries like Singapore, China, and South Korea have made significant strides in the 3D printing realm. Their advanced technological ecosystems and heavy investments in R&D pose competitive challenges for Malaysia.

The Future of FDM 3D Printing in Malaysia

The future for FDM 3D printing in Malaysia looks bright. The continuous support from the government, coupled with investments from the private sector, indicates a positive trajectory. Additionally, as more sectors realize the benefits of FDM 3D printing, its adoption will likely proliferate.

In conclusion, FDM 3D printing technology is not just a passing trend in Malaysia; it’s a transformative force. As the country continues to innovate and invest in this technology, Malaysia stands poised to be a significant player in the global 3D printing landscape.